Manufacturing Capabilities

The One-Stop Shop for Magnetic Solutions

We are extensively vertically integrated which allows us to produce e.g. cores, components, stamped parts, lamination stacks and permanent magnets with full control over the material properties. This simplifies business for our customers and clarifies responsibilities between all steps within the value chain. At the same time, we have an extensive interface to various industries on all levels of the value chain, which helps us to understand present and future market requirements comprehensively. This enables us to focus our research and development teams accordingly.

Capabilities

VAC is the only soft magnetic material manufacturer in the world to further refine its materials into stamped parts, lamination stacks and high-class rotor-stator systems. Laminations are being manufactured using either stamped and laser welded single laminations, cost-effective interlocked packages or EDM production for VACSTACKS® . The combination of our production technologies and the high-end soft magnetic materials moves all customer’s applications to the edge of technology and market leadership allowing the development of extremely powerful and efficient motors or other crucial magnetic components in various applications.

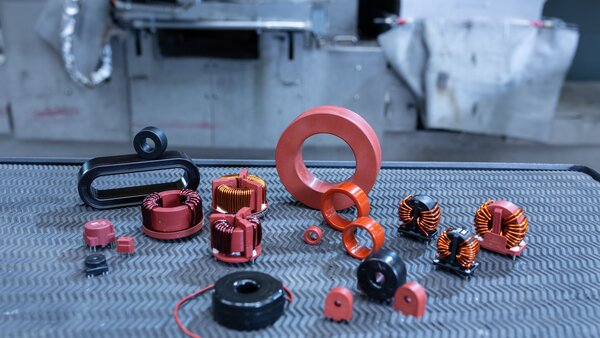

Based on our rapid-solidified, nanocrystalline material VITROPERM® , we produce cores and common mode chokes for EMC applications which feature extremely high permeability in combination with lowest coercivity and excellent thermal properties.

Thus, cores or CMCs are build in the smallest sizes, are suitable for high currents or high voltages and have extremely low losses and excellent attenuation over a wide temperature range.

We are the largest manufacturer of rare earth permanent magnets in Europe, however, the global competition is intense. We are maintaining our market position by constantly improving our manufacturing processes and by increasing our automation share. This allows us to focus on applications with very tight tolerances and demanding magnetic properties.

VAC is the only soft magnetic material manufacturer in the world to further refine its materials into stamped parts, lamination stacks and high-class rotor-stator systems. Laminations are being manufactured using either stamped and laser welded single laminations, cost-effective interlocked packages or EDM production for VACSTACKS® . The combination of our production technologies and the high-end soft magnetic materials moves all customer’s applications to the edge of technology and market leadership allowing the development of extremely powerful and efficient motors or other crucial magnetic components in various applications.

Based on our rapid-solidified, nanocrystalline material VITROPERM® , we produce cores and common mode chokes for EMC applications which feature extremely high permeability in combination with lowest coercivity and excellent thermal properties.

Thus, cores or CMCs are build in the smallest sizes, are suitable for high currents or high voltages and have extremely low losses and excellent attenuation over a wide temperature range.

We are the largest manufacturer of rare earth permanent magnets in Europe, however, the global competition is intense. We are maintaining our market position by constantly improving our manufacturing processes and by increasing our automation share. This allows us to focus on applications with very tight tolerances and demanding magnetic properties.