SmCo Permanent Magnets for Electric Turbocharging and Fuel Cell Air Supplies

VACOMAX 262 TP represents a new Benchmark

The requirements on the automotive industry to reduce CO2 emissions from vehicles with internal combustion engines and hybrid electric vehicles are accelerating the trend toward electric turbocharging. Electric turbochargers are an option to simultaneously improve the performance and reduce the fuel consumption of plug-in and mild hybrids.

Consequently, the demands on the materials used in these engines are continuously increasing. The new alloy VACOMAX® 262 TP is the ideal material for the electrification of auxiliaries as it provides excellent magnetic properties at high temperatures.

Benefits of VACOMAX 262 TP:

- High remanence Br of 1.17 T (at room temperature)

- High coercivity HcJ of 1,590 kA/m (at room temperature)

- Max. operational temperature 250°C

- Excellent corrosion stability

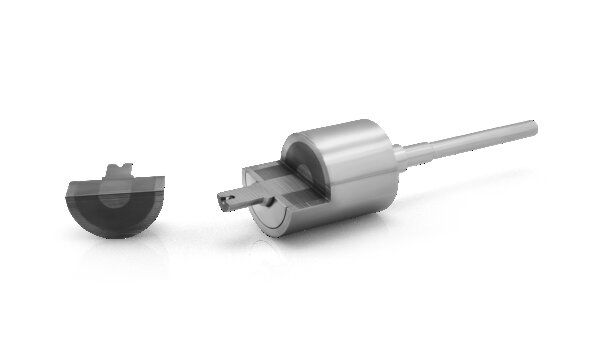

The photo shows VACOMAX rotors with bandages for electric turbo chargers. The left image shows an example with the shaft going through the permanent magnet, whereas the right image shows an example with a longer sleeve that can be connected to a rotor shaft.

Electric Turbocharging for ICE or Fuel Cell Air Supplies for Hydrogen Electric Vehicles

The ability to control the fuel-to-air-ratio with an electric turbocharger during combustion leads to cleaner engines. In addition, a more dynamic driving experience through the

elimination of the turbo-lag makes electric turbocharging an attractive auxiliary device for the car industry.

Besides battery electric vehicles, hydrogen fuel cells will play an important role in next generation mobility. In the fuel cell stack the hydrogen reacts with oxygen from air and provides electricity for the traction motors. The fuel cell air supply needs to be driven by compact, highly efficient air-compressors to achieve the required airflows.

Such air-compressors as well as electric turbochargers use high-speed permanent magnet motors connected to the impellers. Rotation frequencies of over 100.000 RPM and the need for low latency lead to application temperatures around 200 °C.

Their excellent high temperature magnetic properties classify permanent magnets made of SmCo the ideal solution for such applications.

The high performance grade VACOMAX 262 HRP with a significantly higher energy density compared to previously available SmCo grades, leads to designs that are even more compact and can withstand the required application temperatures of up to 250 °C.

Furthermore, due to VAC's unique high yield single part pressing technology, this grade is available for the high volume demands of the automotive industry.

Temperature Dependence of Energy Density of different SmCo (VACOMAX) Grades compared to NdFeB (VACODYM®) Choose between highest performance and best scalability

For the high volume demands of the automotive industry VAC's high-yield single part pressing technology is the optimum solution. This production technology is used for VACOMAX 262 TP grade.

For highest performance and medium quantity applications, VACOMAX 262 HRP is recommended. The isostatic pressing used for VACOMAX 262 HRP leads to an even higher remanence.

Both grades offer a significantly higher energy density compared to the previously available VACOMAX 225.

Typical Demagnetization Curves B(H) and J(H) at different Temperatures

The temperature dependence of the demagnetization curves shows the excellent high temperature properties of VACOMAX 262 TP. The low temperature coefficient of remanence and coercivity enables simple motor designs up to temperatures not accessible with NdFeB. This can make the demand for cooling obsolete which leads to an overall reduction of complexity and system cost.

Download

Related Products

SmCo-Magnets VACOMAX

VACOMAX® is our permanent magnet material made from rare-earths and cobalt. These magnets have particularly high coercivities with simultaneous high saturation polarization and excellent temperature and corrosion stability.

NdFeB-Magnets VACODYM

VACODYM® magnets are produced on the basis of neodymium-iron-boron alloys and have the highest energy density available today. VACODYM alloys are anisotropic material grades.

Magnet Assemblies

The positioning of magnets with extreme precision, especially small one, and the very high forces associated with large-volume magnetized parts, make the assembling of magnet systems a challenging task. For this process we can apply our extensive experience in the design and construction of assembly tools and our expert knowledge in the selection of a suitable bonding process.