Download our New Brochure

VAC excels in providing solutions for next generation electric motors - with permanent magnets, magnetic materials and components made for mission-critical requirements in the field of automotive, aerospace and defense as well as industrial applications.

Learn about our capabilities and our unique one-stop production.

40 to 50 % Nickel-Iron PERMENORM®

Alloys with a Ni-content of around (40...50) wt% are characterized by a maximum in the saturation polarisation of up to JS = 1.6 T and a medium range permeability. By selecting appropriate rolling and annealing conditions, the shape of the magnetization curve can be varied over a wide range.

49 % Cobalt-Iron VACOFLUX and VACODUR

Thanks to their high magnetic saturation of up to 2.4 T, the cobalt-iron (CoFe) alloys VACOFLUX® and VACODUR® are generally suitable for all applications where high flux density and minimum weight are required.

Qualities with a cobalt content of 49 % and 2 % vanadium are offering in addition low coercivity forces and therefore best possible parameters for highest performance electric motors/generators and magnetic actuators.

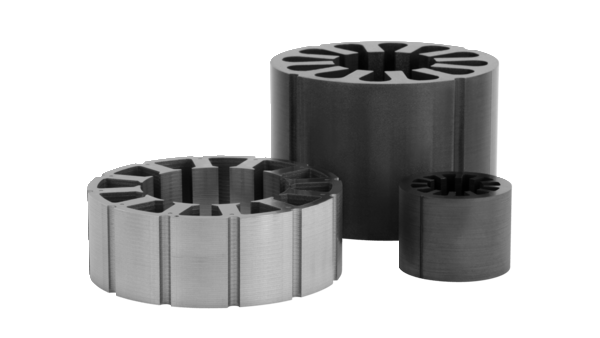

Lamination Stacks

Lamination stacks are packages using single laminations separated by electrical insulating layers to surpress eddy current losses during dynamic magnetic load.

In-house manufactured cobalt-iron or nickel-iron strips in combination with adjusted production technologies are offering optimum stack solutions with respect to performance and costs.

These parts are mainly used as stators and rotors in electric motors and generators but also as laminated cores.

Magnet Assemblies

The positioning of magnets with extreme precision, especially small one, and the very high forces associated with large-volume magnetized parts, make the assembling of magnet systems a challenging task. For this process we can apply our extensive experience in the design and construction of assembly tools and our expert knowledge in the selection of a suitable bonding process.

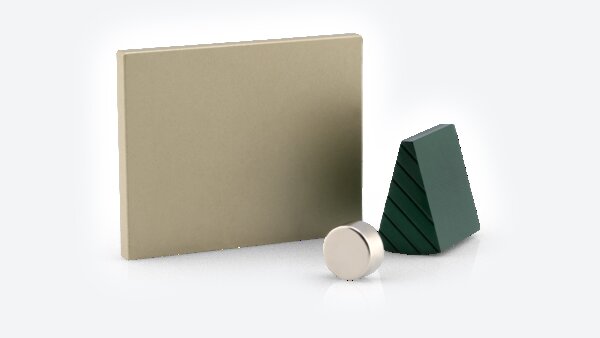

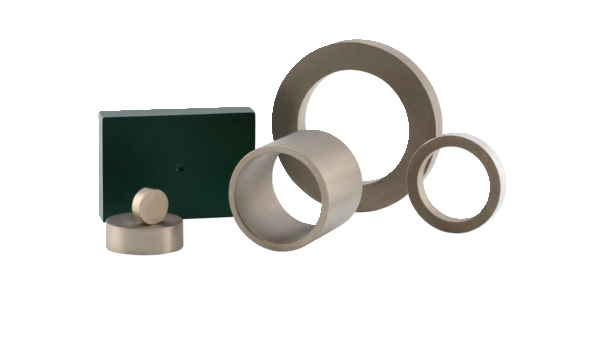

NdFeB - VACODYM

VACODYM® magnets are produced on the basis of neodymium-iron-boron alloys and have the highest energy density available today. VACODYM alloys are anisotropic material grades.

SmCo - VACOMAX

VACOMAX® is our permanent magnet material made from rare earths and cobalt. These magnets have particularly high coercivities with simultaneous high saturation polarization and excellent temperature and corrosion stability.

Soft Magnetic Stamped Parts

All crystalline alloys can be processed further to stamped parts. VAC has state-of-the-art facilities for punching, deep-drawing and further processing methods like interlocking or wire-EDM.